Blackline Safety is a technology leader driving innovation in the industrial workforce through IoT (Internet of Things). With connected safety devices and predictive analytics, Blackline enables companies to drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics to meet demanding safety challenges and enhance overall productivity for organizations with coverage in more than 100 countries. Armed with cellular and satellite connectivity, Blackline provides a lifeline to tens of thousands of people, having reported over 200 billion data-points and initiated over seven million emergency alerts. For more information, visit BlacklineSafety.com and connect with us on Facebook, Twitter, LinkedIn and Instagram.

Your Complete Guide to Lone Worker Safety Devices

Blackline Safety, Leader in Connected Gas Detection & Lone Worker Safety

April 21, 2021

Employers have a legal obligation, known as duty of care, to keep employees safe in the workplace. This can be accomplished more easily when workers are together in central locations, but more challenging when companies employ lone workers who are out in the field. Fortunately, today’s technology — including lone worker safety devices — can help with the heavy lifting to keep these workers protected.

Overview of Lone Working Devices

This concept of lone workers isn’t new. People have been working alone for thousands of years, often only protected by their own wits or primitive solutions. For example, some native tribes in North America would use smoke signals. In this system: “one cloud of smoke meant to pay attention, something is going on here; two meant all is well, and three meant danger or help.”

This concept of lone workers isn’t new. People have been working alone for thousands of years, often only protected by their own wits or primitive solutions. For example, some native tribes in North America would use smoke signals. In this system: “one cloud of smoke meant to pay attention, something is going on here; two meant all is well, and three meant danger or help.”

Another example, in 1911, canaries were first used in mines to help detect dangerous gases. A man named John Scott Haldane came up with this idea, recognizing that canaries were more susceptible to CO exposures and other poisonous gases than, say, mice. If these canaries became ill or died, this was one of the earliest warning systems that could indicate a gas hazard. It wasn’t until 1986, that digital detectors called “electric noses” began being used.

As employers have become increasingly more responsible for their employees’ safety, savvy companies are investing in more effective solutions – particularly as technology has improved. You can perform a lone worker risk assessment to determine what you need for personal gas detection and safety devices.

Lone Worker Connectivity

The Blackline Safety line of G7 products provides companies around the globe with the technology to protect their employees from hazards in the field such as combustible and toxic gas detection, no-motion, missed check-ins and fall detection. And 24/7 live monitoring gives employees and supervisors the ability to stay connected and communicate with one another from anywhere in the world.

The push-to-talk feature on the G7 devices helps employees stay connected by giving them the ability to quickly call co-workers on the same channel, or as needed, they can simply switch to the appropriate channel to talk with specific teams no matter their location. There is no radio licensing required (as there is with conventional radios) and there is no range limit.

In other words, your company can combine lone worker communications with world-class gas detection in a single device which saves money by streamlining equipment, maintenance and operations by reducing the number of devices a worker is required to carry every day.

This can be the ideal solution within one, or multiple, worksites. Your company can configure push-to-talk on their G7 devices with built-in cellular technology allowing your employees to benefit from connectivity right out of the box – eliminating the need for a second standalone device for communications.

G7 offers two connectivity options:

With G7c, when an emergency happens, your workers are 3G/4G-connected for maximized evacuation management of everyone’s safety via the Blackline Live portal showing the position and status of every device in real-time.

G7 uses a pending alarm if no motion is detected, the occurrence of a potential fall through impact and device angle change, or if a scheduled check-in is missed. These alarms require that the affected worker confirm they are safe. If acknowledgement of the alarm is confirmed, then you are assured of their safety. If there isn’t a response, live monitoring teams receive an alert to follow pre-established emergency response protocols.

The workers can also manually trigger an alert themselves for scenarios outside of the automated safety protocols (e.g. heart attack symptoms or severe weather) by pulling the G7’s red SOS latch for immediate assistance from monitoring personnel.

For true last-mile connectivity, there’s G7x. This seamless satellite technology uses an industrial-strength radio link to connect with the G7 Bridge base station to provide the widest reach in lone worker safety monitoring available today. Lone workers can park their truck with the Bridge, wear the device, and work more than a mile away from it, confident in their real-time safety coverage.

Gas Detection Protection

In our previous example of a low-tech solution for detecting gas, the canary was chosen for primitive gas detection because of its sensitivity to one particular gas, carbon monoxide. However, today’s workers often face situations where multiple gases are present. Combustible gases, for example, could be hydrocarbons, hydrogen, or other possible flammable gases. Still, other gases are less likely to combust, yet have the potential of causing serious harm due to their toxicity. There are a few options for how to detect and monitor these risks.

Worksite solutions can include a mixture of the following types of detectors for optimal safety:

- Fixed detection monitors

- Area gas monitors

- Personal gas monitors

Fixed monitors serve as a first line of defense and are placed strategically in static positions where an ongoing risk of gas presence exists. They operate continually to provide alarms and play a key role in automating facility shutdown procedures and worker evacuations when a potential threat is detected.

Area gas monitors provide another layer of protection, independent of overall infrastructure on the worksite. They are ideal for places where fixed detection monitors aren’t suitable, like outdoors, and can be easily moved to a new temporary location as needed, including during emergency situations.

Personal gas monitors are, as the name suggests, protection devices intended for individual workers. They’re worn to detect gas presence within a worker’s personal breathing zones and, when it reaches dangerous levels, an alarm warns of a need to evacuate.

Advances in Gas Detection Technology

Gas detection technology has continued to advance, with an important development occurring in the 1920s. That’s when Dr. Oliver Johnson of Standard Oil Company (now Chevron) created the catalytic combustion (LEL) sensor that relies upon pellet-resisters (or pellistors). These beads are the most commonly used system to detect combustible gases today.

About 50 years later, a patent was filed by Koz Ishida for a new gas detection system: non-dispersive infrared (NDIR) sensors. These sensors use infrared light shone through a gas sample at a specific wavelength. The returning wavelength is then analyzed. If weaker, this indicates the presence of hydrocarbon gases that absorb infrared light.

This type of technology has continued to advance, although the foundational principles remain the same. Both of these types of detection technologies — pellistors and NDIR — are used in today’s workplaces.

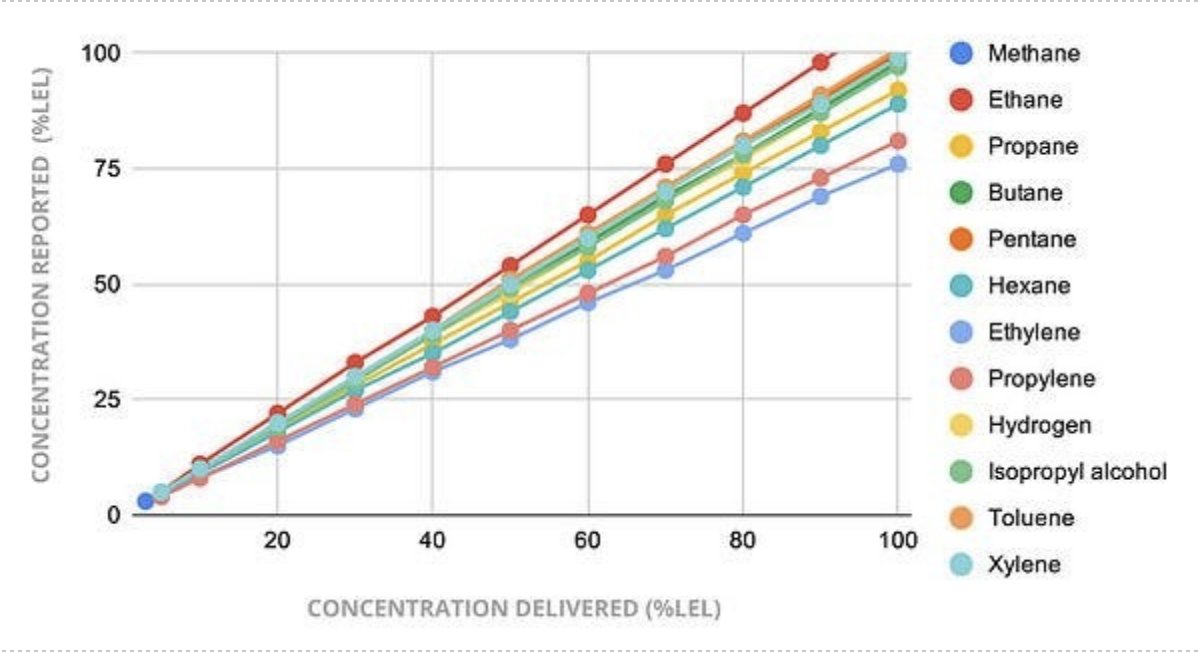

Until very recently, there have been no significant developments in sensor technology. However, in October 2018, NevadaNano launched a breakthrough in the gas detection industry with the release of the Molecular Property Spectrometer (MPS™) sensor for combustible gases. This sensor is much more accurate than both pellistors and NDIR sensors, resulting in decreased costly and time-consuming evacuations from false alarms. The MPS sensor also detects an unprecedented 12 different combustible gases including acetylene and H2 and is immune from poisoning from substances like silicones (e.g. WD-40) that render other sensors useless. It can also classify the detected gas into various categories, indicating what type of combustible hazard you are dealing with so that proper responses can be initiated.

G7 Cartridges For Complete Lone Worker Safety

G7 is expandable with interchangeable cartridges so you can completely customize your company’s lone worker safety program. The choice of the standard lone worker without gas detection, single-gas, multi-gas, or multi-gas with pump cartridges gives your employees the monitoring capability for every role they need to keep them safe.

Confined Space Gas Detectors

Confined spaces naturally tend to have reduced ventilation, which creates environments where toxicity-related dangers are higher. When workers need to enter a confined space, the G7 multi-gas pump cartridges, with a sampling hose of up to 99 feet, allows workers to check gas toxicity levels to ensure the space is safe to enter.

Visibility into confined space entries around a worksite is also taken to the next level with assisted GPS technology. Each confined space would first be tagged for location mapping, which allows your company to see when and where a worker enters a mapped space. And with the use of location beacons in conjunction with floor plans, visibility of entries is retained even without a direct GPS signal and for different floors or levels. You can also see how long a worker remains in that space and their peak exposure to gas during that time.

Lone Worker Monitoring

Standard G7 cartridges (without gas monitoring) provide your company with real-time situational awareness, functioning as lone worker monitoring devices that amplify personal safety. Team members with G7 wearables are wirelessly connected to the Cloud in location-enabled ways, with complete customization available to maximize lone worker safety.

Uploaded data can easily be leveraged through Blackline Live for the full picture- visualization, record keeping, and analysis.

Expandable Devices

With plug-and-play configurability, a lone worker cartridge without gas detection can be easily swapped for a G7 diffusion cartridge, turning the device into a personal gas detector, including the ability to go from a single-gas to a multi-gas detector for up to five gases.

Plus, the connectivity of this technology means that the device data and gas readings are automatically uploaded in real-time — allowing your workers to be confident that their safety is constantly being monitored.

Contract Tracing in the Age of COVID-19

Just a short while ago, this safety concern didn’t even exist. Thanks to the flexibility of modern technology, advances have quickly been made to protect your whole team through automated industrial contact tracing.

Using the same G7 wearables that protect workers against gas detection and lone worker hazards, employee interactions can be mapped. This data streams into, and is stored within, the Blackline Safety Cloud, and then, through the use of Blackline Analytics, contact tracing reports can be easily generated to show the proximity of each worker to their colleagues.

If an employee shows COVID-19 symptoms or tests positive for the virus—contact tracing is key. The report will highlight employees that came in close contact with the positive individual during that same timeframe—these individuals must now arrange to test for the virus and isolate at home, while the remainder of your company can continue operations without completely shutting down. Blackline’s Close Contact reports come with customizable filters to provide powerful insights to support your company’s social distancing initiatives.

24/7 Live Monitoring

Cloud technology has transformed our world, including the ability to manage and respond to safety alerts and alarms. This allows you to protect workers to a degree that wasn’t previously possible.

With Blackline Live’s real-time maps, you can confirm the location and safety status of each worker with just a glance. You can see every alert in real-time and examine the alert history of each device, as needed. You can then proactively take measures to enhance the safety of each worker and worksite.

Live monitoring by trained personnel allows you to rapidly respond to any potential problems. This can be accomplished by in-house monitoring, or through Blackline’s 24/7 Safety Operations Center. Critical insights can quickly be gathered through data available in Blackline Live, with situational awareness information seamlessly provided through lone worker devices.

Blackline Safety Can Help

Blackline Safety provides a full system approach to the technology needed to connect workers and help keep them safe, through cutting-edge detection, monitoring and analytics. With Blackline Safety, you can elevate your employee safety program and protect your most valuable assets: your workers.

Please contact us so that we can help you to meet your most critical safety challenges.

Get In Touch

Let’s start a discussion about your safety challenges and needs.

Related Blog Posts

Real-Life Incident: Henry’s Story – Stranded With No Signal

February 25, 2026

"I’m stuck on the scissor lift.”: Connected safety made the save when signals failed. Henry was up on a scissor lift when the battery on the lift...

Real-Life Incident: Mason’s Story — High H2S Exposure

November 25, 2025

“Shortness of breath. Request EMS to the location.” How Real-Time Gas Detection Led to a Quick Save Exposure to toxic gases can go from a strange...

Real-Life Incident: Gerry’s Story: Alone in the Boiler Room With CO

October 21, 2025

When a routine patrol became a potential gas poisoning tragedy, quick action and life-saving technology made all the difference. It was a routine...